Sensor mass air flow (MAF 2112-1130010) is a hot-wire sensor type (see photo 1) and sends to the controller pulse-frequency signal (2-10 kHz) varying in direct proportion to the passed through it, the amount of air.

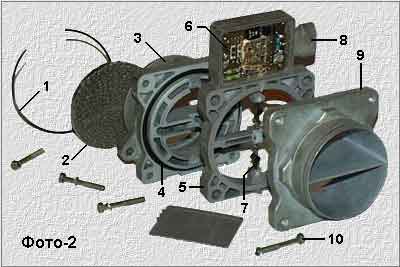

The greater the amount of air passed through the sensor, the higher the frequency of the signal MAF. Accordingly, the number of mastered through the air sensor depends on the angular position of the throttle valve and the idle speed regulator, which is fed through the air to bypass the throttle. The frequency of pulses DFID controller judging the amount of air entering the engine and, therefore, it regulates the opening of the fuel injectors, thus providing the required ratio in the fuel mixture of air and fuel. DFID includes (see photo 2): 1. Ring-retainer filter. 2. A filter. 3. The inlet flange. 4. Sealing rubber ring. 5. The sensor housing. 6. e cost. 7. The thermocouples. 8. Pin connector. 9. The exhaust flange. 10. Screws of fastening elements.

The design of this sensor uses three thermocouple. One (Central) is used for determining the temperature of its environment, and the other two heat the air to a predetermined temperature above the temperature of the ambient air. The mass flow rate of air is determined by measuring the electrical power required to maintain a given excess temperature, and converting this value of power in a pulse-frequency signal. The filter serves to prevent the sensor housing of large particles that may damage the thermocouples. In addition, he acts as a divider of air to ensure uniform air flow. The filter is installed in the intake flange and lock ring retainer. Rubber o rings are installed on both sides of the sensor housing and serve to prevent air leak. Special attention deserves the o-ring between the sensor housing and the exhaust flange. If the location will leak air, it can not be taken into account by the system, which will lead to the depletion of the fuel mixture. In this case, to ensure the optimal operation of the engine is almost impossible, because in the system "January 4" is not provided feedback on the lambda probe. Identify air leak without the use of special multitester is problematic.

DFID is installed (see photo 3) between the air filter and air hose to the throttle body. For dismantling DFID needs with the ignition off disconnect connector, disconnect air hose and remove the two screws securing the sensor to the air filter. Installation should be carried out in reverse of the disassembly sequence.

The DFID resource is not regulated and largely depends on the condition of the air filter. Getting into the sensor housing foreign particles can incapacitate him. If faults occur, DFID, in memory of the electronic unit control error code is stored "33" or "34", which can be read with the lamp "CHECK ENGINE" in read mode codes or a multitester. It is lit the lamp, and the controller calculates a value of air flow rate based on signals of the sensor, throttle position sensor and crankshaft position.

Symptoms of malfunction MAF can serve as the stop of the engine when shifting gears while driving, the failures in the operation of the engine under load and at idle. Lamp "CHECK ENGINE", this often does not illuminate and identify this fault means at hand can be difficult. When the diagnosis system is necessary to carefully examine the nature of the work of the engine in a variety of modes and to compare the response of the sensors to one or another symptom. Can be recommended to follow a process of elimination of all possible causes checking of the respective sensors. Note that the sensor mass air flow is a precise measuring instrument and, as practice shows, are "afraid" of the body.

Publication: www.cxem.net