Sensor vehicle speed (ACD) designed on the principle of Hall effect and gives the controller pulse - frequency signal. The frequency of the signal is directly proportional to the vehicle speed. The controller uses this signal to control the operation of the engine at idle speed through the idle speed regulator controls the flow of air to bypass the throttle. The ACD provides approximately 6004 pulse at each kilometer traveled by the vehicle path. According to a time interval between pulses, the controller determines the vehicle speed. In addition, this signal can be used by a speedometer mounted on the instrument panel. The appearance of the gauge of speed of movement of the vehicle shown in photo 1.

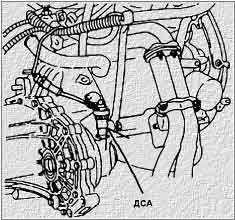

The ACD is mounted on the gear box (see photo 2) on the mechanism of a drive of a speedometer.

Dismantling after it is produced (with ignition off) disconnect the connector and cable drive speedometer (if installed) by unscrewing the sensor from the drive of a speedometer. Installation of CSA produce disassembly instructions in reverse order. When fault circuit connection, the ACD, the controller enters into the RAM code is "24" and lights the lamp "CHECK ENGINE", thereby indicating the need for diagnostics. One of the clearly marked symptoms of failure of the speed sensor is used to stop the engine at idle when the car is coasting. But we should not forget that a similar situation may occur with temporary malfunctions of the sensor mass air flow (MAF), but the lamp "CHECK ENGINE", in this case, not always lights up. On this basis it is possible to pre-judge whether the sensor has failed. Checking the health of the ACD should start with the presence of ground on pin 3 and the supply voltage (+12V.) to contact "1". Checking for a pulse on terminal "2" should be carried out during rotation of the drive wheels at a speed of not less than 5km/h. To make measurements, I recommend a digital multimeter or an oscilloscope. To check for "1" and "3" contact the ACD is permitted to use the continuity test. Typical symptoms of a faulty speed sensor or Alcee include the stop of the engine when shifting and coasting, the error of the speedometer.

Most often the failure of CSA is associated with the operation of the speedometer cable. If the cable has on its surface any burrs, breaks, or simply hindered it from rotating in a protective sheath, it can lead to failure of the speed sensor (see photo 3 and 4). Furthermore, it is often because of this reason the speed sensor fails precisely at high speed. On photo 3 metal rod, which is passed on rotation, melted plastic and, as shown in the photo, just fell out. On the other hand, the speedometer cable just broke your seat and respectively stopped it in to be fixed, which led to failure of the normal operation of Spiderman (see photo 4). Since the electric circuit of the sensor was not damaged, the lamp "CHECK ENGINE" was not lit because of the lack of recorded errors of a given circuit. In this case, the problem was solved simply by replacing the speedometer cable and speed sensor with new ones. To avoid such situations, while the speedometer cable is defective, it should be lubricated with engine oil.

Photo 5, 6 and 7 shows another variant of the speed sensor (301.3843).

This sensor has a metal shank, which is less susceptible to wear. If you are not afraid replacement connector, better is faulty. CSA replace on that.

Publication: www.cxem.net