The crankshaft position sensor (see photo 1) is an electromagnetic sensor, in which the fuel injection system to synchronize the operation of the fuel injectors and ignition system. In this regard, ДПSW is a key, without which the work of the fuel injection system is impossible.

Failure ДПSW inevitably lead to a malfunction of the engine. Although malfunction crankshaft position sensor are not as often, going on a long journey, it is better to have a defective sensor in stock, because in cases of failure of ДПSW further movement of the car may not be possible. The crankshaft position sensor mounted on a bracket near the pulley of the generator (see photo 2).

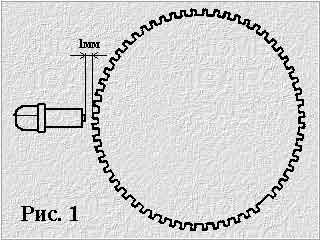

ДПSW is installed with a gap between the sensor and the toothed pulley. The gap should be about 1 mm. (see Fig. 1) and exposed to the selection of appropriate washers.

A toothed pulley of the generator is in the form of a special drive that contains 58 teeth every 6 degrees. To generate a sync pulse turns on the crankshaft pulley is missing two teeth (see photo 2 and Fig. 1). The car can be a metal pulley or damper (rubber spacer). In the operation of a vehicle, all-metal pulleys wear almost not affected. It is only necessary to follow the lack of between the teeth of any foreign particles and dirt. If the pulley with vibration damper, it is necessary to monitor his condition, because the damage of the damper can cause problems in the engine. In case of repair works should be careful and not expose the pulley deformation, because it can lead to malfunction of the engine. Visual inspection of the condition of the pulley of the generator it is possible to make through the arch of the right front wheel, as shown in photo 3.

In this case, the car has a metal pulley. Note * if the crankshaft position sensor, the pulley of the generator and the timing controller may fix the error and to light the "CHECK ENGINE". Accordingly, in the buffer error code will be entered "35" and/or "19" To the problems of these elements include the following symptoms: erratic engine speed at idle, spontaneous increase or decrease engine speed, stop the engine, failure to start the engine, reducing engine power, the occurrence of knocking under dynamic loads, omissions sparking. In photo 4 and photo 5 shows the pulley of the generator with a damaged damper.

This fault has resulted in the inability correct synchronization of the phases of the injection and ignition, because the inner part of the pulley is moved relative to the gear wheel and the phase of the injection and ignition turned off. After replacing the pulley on a healthy malfunction of the engine ceased.

Publication: www.cxem.net