Photo 1 shows the idling regulator unassembled. Immediately say, that the disassembly of the IAC should be made with some caution. Otherwise, it is likely permanently incapacitate him. In order to disassemble the IAC must be removed from its housing three locking studs. After that, with little effort to remove the connector housing so as not to damage the wires and solder them.

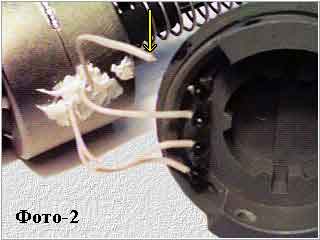

One of the faults that I have ever encountered, it is an internal broken wires (see photo 2).

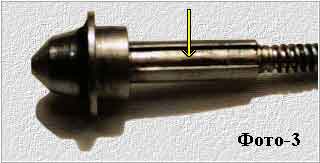

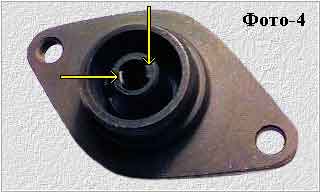

After soldering, cut off from contact of the connector of the conductor, the normal operation of the IAC was able to recover. It should be noted that the soldering after repair should be rinsed with alcohol and varnished in order to avoid possible corrosion of the contact. Alas, this is perhaps the most simple malfunction of the idle speed regulator, which is easy to remove without any problems. Other faults to fight much harder and more often you need to replace the IAC with a new one. These failures can be attributed to the production of the guides for the cone of the needle and/or its actuator. Tapered needle has special grooves that are included in the grommet (see photo 3 and 4).

When the guide rail bushings tend to wear out. As a result of the conical needle starts to rotate in the sleeve, which leads to the impossibility of translational movement of the needle. Accordingly interferes with the normal operation of the engine at idle, because these translational movements of the conical needle opens or closes the channel for more air to bypass the closed throttle. A similar situation also leads the development of the drive cone of the needle. Unfortunately, I was not able to make high quality photos with his camera because of focusing problems.

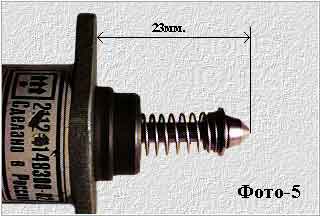

In conclusion, it should be recalled that before installing the IAC in its place, you need to correctly set the initial position of the conical needle. Between the flange IAC and the end point of the needle should be 23mm (see photo 5).

This gap is necessary so that when mounting the IAC its tapered needle might Balk at the saddle on the throttle body. The gap is set by the special multitester or driver control pulses to control idling. In addition, the o-ring on the mounting flange IAC should be lubricated with engine oil. Installation and connection of the connector of the idling regulator should be carried out when the ignition is off.

Publication: www.cxem.net