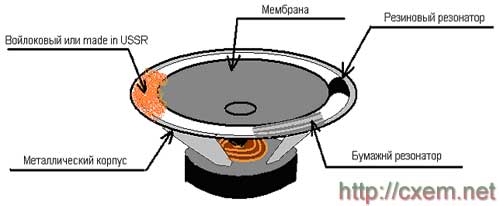

The article describes the technology of restoration of the resonator speakers.

If the resonator dynamics came to an end, and the appropriate size and especially the new one is not, it is not necessary to send a speaker to the light! There is a way!

1) If the resonator is torn but is still on site (residues), it is necessary to completely remove (crop, unstuck is to eliminate), leaving only the membrane and the metal casing with a space between each other.

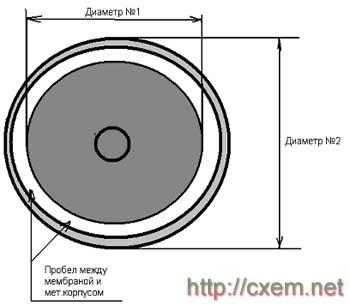

2) Next, we need to measure all diameters:

1. The diameter of the membrane - No. 1

2. The diameter of the metal body (which is mounted resonator) - No. 2

3. In the case of egg-shaped speaker, I think everything is clear.

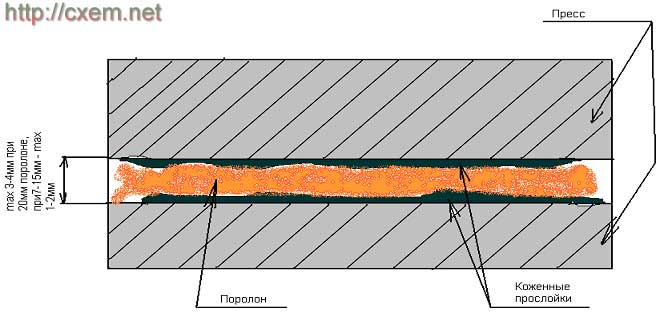

3) Take the foam, its thickness depends on the size of the membrane (dynamics)

The diameters of the speakers The thickness of the foam 7-10cm 5-7mm 10-15cm 8-13mm 15-20cm 15-17mm 20-30cm 20-30mm (if found)4) Cut the foam

"outside diameter by 5-10mm longer (No. 2), (depends on the speaker size and the possibility of its stroke (amplitude));

"inside diameter by 5-10mm lower (No. 1), (diaphragm diameter).

5) Fluff (to impregnate) the foam glue "Moment", and put under the press with leather layers (to avoid unwanted results).

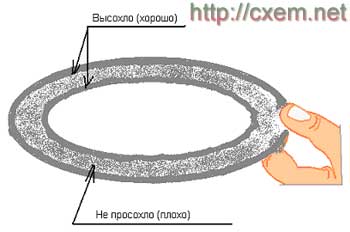

6) in a day to remove the press center is not naturally dried up, but the main thing dried up the edges and thus, they were not straight, but with the center have a little caress!

It should be perminate (compress) your fingers until the glue (5-7 minutes).

7) Next, glue the foam first to the membrane at the bottom or top as you like (but of course stretchable so that the foam was higher on the membrane), and then to the metal body and the bend is by itself (due to the fact that the foam is wider than the space between the membrane and the metal housing).

8) the Resonator is ready, but if you want to fluff again resonator "Moment" from the top (stronger).

And here are examples of what can happen

Satellites 2x15 Watt (auto dynamics 8.5 cm) (stroke 11-14mm):

But my subwoofer (diameter 20 cm - 8 inch) (its working stroke 30mm) to tunnig he demanded 15 Watt, and now he needs 60 Watt (well, very elastic). He is now in a box on 27 liters with "fathom":

The system of fastening the foam to the membrane completely different (experiment, but firmly).

The layer of foam cut along the inner diameter (depth 4mm), and in the resulting gap pasted (inserted) membrane.

Authors: Alexander Larin (Speaker) and Konstantin Zolotarev (*KONSTANTIN*); Publication: www.cxem.net