Time to cut pianos

Full sound transmission today is unthinkable without the low-frequency component of the acoustic of the signal. Therefore, more and more drivers who are not indifferent to the quality of sound in the car, complete stereo and a pair of columns (as they would say American installer "deck and two") speakers that extend the reproduced sound range towards the top, and especially the lower limit.

Since the signal is 20 Hz - 150 Hz has no practical effect on the stereo, decided to allocate it to one channel issued one acoustic enclosure, simplifying circuit design and storing the interior space of the vehicle. And due to the fact that the sound in the bass region frequencies covered, avoiding obstacles, to place the subwoofer enclosure at any spare car parts. Acoustic box is made of different materials: plywood, chipboard, plastic. There are some masters who use wood from musical instruments.

Acoustic design the subwoofer, if it is not set already finished parts factory manufacturing usually includes: design and calculation of acoustic systems for specific order, manufacturer of acoustic enclosures and installation of the system in the car. Since the acoustic design of subwoofers requires creativity, each master installer finds her own key to its implementation. Agreeing with the client the fundamental issues, the wizard proceeds to a detailed calculations of the future of acoustics. Dozens of schemes enclosures for subwoofers can be reduced to several main types, among which the most famous are closed, a phase-system and system with passive speakers.

When designing a subwoofer speaker system usually seek to get a good transfer function, that is good value created it sound pressure and complex input signal. The transfer function of the three systems are similar in principle to the transfer the functions of the high-pass filter, respectively, the second and fourth order, with the slope of the amplitude-frequency characteristics in the direction of low frequencies 12 dB / octave and 24 dB / octave, and the resulting frequency response in the area of operating frequencies the subwoofer depends on the characteristics of the dynamics, applied filter crossover, construction and housing, as well as opportunities the power amplifier. Considering all these features in the acoustic design subwoofer, masters tend to reduce the amplitude of displacement of the movable system dynamics and thereby raise the level of the input electric power, and also maximum sound pressure that will help to reduce congestion and signal distortion.

For a thorough study of design today to use special computer programs calculate, laying on input parameters of the subwoofer and getting "out" recommended specifications of the speaker Cabinet. Sometimes, to calculate some volume characteristics of the housing master installer has to use and "equivalents": if the manufacturer of the subwoofer makes recommendations regarding types of acoustic enclosures and volume, to calculate its own volume subwoofer volume izmadenova they air, due to complexity of its geometry can be difficult. Some meticulous installers sometimes use any homogeneous granular substance (not able, of course, damage surface dynamics), filling and measuring equivalent volume izmadenova air.

The acoustic enclosure is the most important element of the whole acoustic subwoofer system. It needs not only to have the optimum internal volume to accommodate dynamics and necessary components, but also to have a sufficient strength is not only mechanical, and acoustic. The fact that the dynamic subwoofer type operates as a pump, sealing the air in front of the diffuser and razreda it with rear side in the axial direction. Thus the pressure on both sides are equal but reversed in phase, so in the absence or insufficient isolation of the front and rear surfaces of the dynamics will take place "acoustic short circuit." To avoid it, you need to ensure the phase shift of the acoustic signal radiated from the back side of the diffuser, for example, a half wavelength. This is achieved through the installation of sound -panel walls", most often in the form of a closed housing. More than this partition (or more volume of the shell), the theoretically lower the tone signal, which is not acoustically closed.

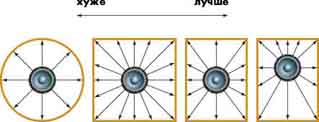

If the volume of the body (ie. the value enclosed in it air mass) affect the height of its resonant frequency, the shape of the hull affects primarily the formation of standing waves in the result of his own chassis resonance, occurring at varying frequency. To fight with the formation of standing waves, resort to offset speaker from the acoustic center of the housing. The most unfortunate is considered when this cubic form of acoustic Cabinet with a speaker located on equal distance from its walls.

The location of the speaker relative to the walls corps

The housing design in determines acoustics subwoofer system, although not as important, what materials are used in its manufacture. Today they can be: wood, plastic, organic glass, ceramic and even concrete. The most practical most masters believes coarse particle Board (MDF): they have good insulating properties, affordable, have a uniform density (in contrast to the multilayer plywood), high specific weight and also respond well to carpentry the processing. It should be noted also that the master manufacturing competitive car audio systems, is often used in the manufacture subwoofer enclosures exotic or transparent materials due to their unusual properties, and in the pursuit of external originality or desire to demonstrate the internal structure of the system.

System closed type

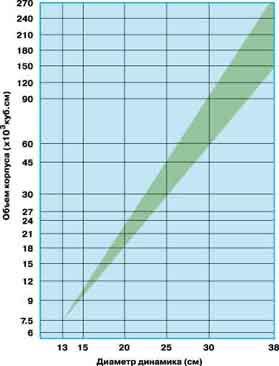

The optimal size of buildings subwoofers

This type of system have good acoustic performance with constructive simplicity. The volume of the shell determines the frequency in which you installed the subwoofer will have the optimum characteristics: if the volume is insufficient to this dynamics, the pressure inside the housing will be higher than outside, and the lowest tone will be attenuated. With further decrease of its volume the loss of low-frequency component will increase and a higher tone, on the contrary, emphasize, reinforcing the "barrel effect", instead of a dense and clear the bass. Therefore, the lack of space it is better to use the subwoofer is smaller, for example, 8-inch, instead of to limit the body of a 10 - or 15-inch speaker.The increase in the volume of the hull above the manufacturer's recommended subwoofer can to improve the impact at the lowest frequencies, however, the wizard will face even big problems when it is installed in the vehicle. The graph above describes the recommended optimal size of enclosures for subwoofers different diameter.

A phase system

In search of a more effective patterns of low-frequency acoustic design speakers wizard already decades ago began to use the housing with the inverters and acoustic ducts of various types. Interest particularly increased in recent years, with the development of hi-fi equipment due to they allow you to extend the frequency range. Some masters consider justified to spend additional efforts to go further closed-back design and get the win in the bass response.

In a phase-buildings used cylindrical or rectangular pipe, usually custom to a specific frequency. Acoustic design subwoofer with the use of such buildings requires master installer of large theoretical knowledge and experience, so as to obtain good gear functions have to agree, for example, factors such as mutual the influence of the radiation resistance of the diffuser and the phase inverter tube through mutually collabrasuite the mass of air.

Error, for example, in the calculations of q, as well as the design and configuring port are the reason that speaker system "mumbling" or bass "smeared". And even if the bass reflex tube is configured to the required frequency, it can be a source of nonlinear distortion, if, for example, the volumetric flow rate of air in it exceeds the allowable (it should not to exceed 5% of the speed of sound): in this case, the air flow becomes turbulent. The sensitivity transfer function (sound pressure) a phase system to the detuning frequency of the inverter is very high, and after final Assembly may be required to fine tune.

Evaluating the effectiveness and quality of the sound one way or another subwoofer system, practitioners often use the analysis of the sound level pressure, for example, in third-octave band range of operating frequencies. For measurement at this level and other important characteristics of the finished subwoofer the system can use the tools of a real time analysis (see "12 Volts" N 3 1997). Recognizes the legitimacy of subjective estimates of autoexpert.

Heavy boxes for light bass

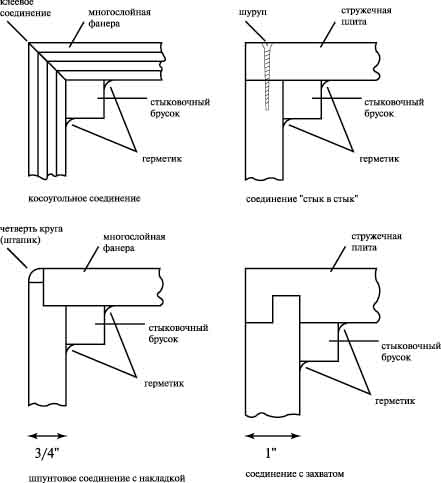

We cannot say that to make the body or the loudspeaker for car subwoofer it is extremely difficult. If you follow the instructions and recommendations of experts, then even with a limited set of hand tools capable master able to make a quality sound system. As noted above, masters often use particleboard type MDF with the necessary mechanical and acoustic properties. Less likely to use multi-layer plywood. Depending on the skill of the master in woodworking the difficulty for him can imagine sawing and fitting surfaces of the box in the corners. It is especially difficult to achieve high-quality connections, using only hand tool. "Popular" in the manufacture of such structures the articulation surfaces on the principle of "dovetail" is not appropriate, as most of chipboards and plywood panel, has not the required mechanical strength of the structure of the adhesive composition and particle the filler. The figure shows some types of corner joints, used in the manufacture of boxes, car subwoofer systems.

View masters

Victor Polyakov, the company "Russian Game"We learned that customers who appreciate quality sound car audio system, prefer bass reflex designs despite the additional costs. Moreover, the manufacturers of subwoofers facilitate our task recommendations for calculations casings, tubes and cut-off frequency crossovers.

We also checked that the use of high quality materials for acoustic enclosures are justified. We use fine particle plate Jamo. For subwoofers perfect inch plate, which is not only durable, well handled, but also has good acoustic properties, without requiring additional surface treatment. For interior use special foam rubber, and for the overall completion of the design of the case is covered carpet and special acoustically transparent materials.

Our company now has a full color gamut of such materials, and it is important that the customer was informed about the available opportunities and versions of acoustics in his car.

Dmitry Gurinovich, "Remers Center"Many customers tend to save a couple of hundred on materials for automotive acoustics, so we found that we can successfully apply 20-mm-thick multi-layer plywood and 15 mm chipboard for the manufacture enclosures subwoofers, especially now that you can use with their Assembly hot plastic, special acoustic glue or glue Flex, which very well kept and creates leaks. Vinyl coating gives good the appearance and integrity, which is important for the conditions of the vehicle. We we believe that this optimal sufficiency is the right approach. When we we get very expensive ordering, it comes in solid wood.

Generally, the choice of materials depends on the financial situation client.

Sergei expert panel, the company SV ArtWhen calculating the boxes in the first place you need to keep in mind what the speaker need to be enclosed in the housing. It is no secret that the manufacturer completes its production specification, which should be specified parameters, say, the same speakers. It is clear that this is largely simplifies the work of the installer. Some firms that produce acoustics, offer a variety of configuration options boxes to one and the same dynamics to get a different sound coloration. This is a big plus when working with a client who has a certain taste in music.

If the installation process has to deal with speaker options which is not known in advance or require more precise rechecking, these the required data can be obtained by own measurements - using the sound chip. It is believed that this method is more accurate, but it is more time-consuming and requires considerable material and time costs.

In principle, for any dynamics can manufacture any boxes configuration. Hard constraints not depends on the goals that pursued by the installer. Take for example a conventional closed box. When a small amount of damping dynamics is very high, and he accordingly able to withstand more power. However, when increasing the volume may to appear hollowness. Increasing the volume of the box, we reduce the hollowness, but this decreases and the limit of input power. Usually we design box which the speaker gives out decent power and not buzzing.

We produce boxes from high quality plywood. And for best quality the sides of the box are made of United special glue two layers of 10 mm plywood. So by the way, the wall thickness is not less than 20 mm; for a 10-inch speaker the minimum acceptable is 15 mm from the Inside of the plywood walls necessarily pasted sound absorbing material.

The trapezoidal shape of the boxes have chosen not by chance. This configuration allows you to immediately exclude a few areas of standing waves. It is desirable that the sides of the box were not parallel, so the line we are quite satisfied. In addition, this form of the box more than justified in view of the configuration of the Luggage compartment of the vehicle.

Publication: www.cxem.net