At home I replaced incandescent lamp with E27 base energy-saving. For the year of twelve these lamps refused four. It turned out in all four burned-out lamps electronic ballast defective, out of order gas-discharge tube. Here and matured thought adjust the ballast to the conventional cheap fluorescent daylight lamp.

Having conducted the experiment, I made sure that the lamp runs perfectly, burns smoothly and bright. Right there for her found good use - replace often blowing the bulb in the lamp by the door of the apartment on a stair cell.

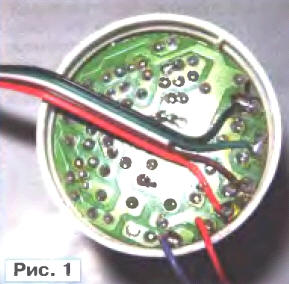

To protect the electronics from dust in the basement disassembled energy saving lamp (Fig. 1) I made for him the plastic cover with a hole, and brought out of it four wires to connect the bulb. Another two are visible in figure wire - temporary. With their help electronic ballast connected to the network during the experiments.

The cap I screwed into the socket side of the lamp. For reaching to the fluorescent the lamp wires in the lamp housing has also been drilled hole. Skipped through it for the wires to install place the glass cover of the lamp. Thus, if the electronic ballast or fluorescent lamp spoiled, you can temporarily return to the lamp bulb.

Fluorescent lamp was installed over the door, as shown in Fig. 2.

If it does not have standard connectors, stripped the ends of the connecting wires can be tightly wound on the bulb pins and close them with decorative covers, for example, from aerosol cans.

On all the work I spent about an hour. In a month at the neighbors on the porch appeared six similar structures. The example was contagious.

Author: O. Petrakov, Moscow

Energy-saving lamps usually burn out the filament, and the electronic part (the so-called electronic ballast) remains intact. The lamp can "revive", connecting to the ordinary ballast fluorescent lamp power 18...30 watts. For this is necessary to carefully open the case of a defective lamp, having separated his with a knife into two parts. By doing this. locate the two pairs of wires extending from the printed Board to the gas discharge tube of the lamp. De-solder these wires and solder other such length that their second ends can be soldered to the terminals standard fluorescent lamps.

Further on the body with two diametrically opposite sides with a knife make the half-circle notches with a radius equal to the radius of the bulb of a fluorescent lamp. Near the notches, stepping approximately a centimeter, heated awl, make two holes.

Cost of ballast with soldered wires cover round or square forms (depending on the hull shape energy saving lamps) with notches for wires. The lid conveniently be cut from a thin non-foiled fiberglass or from used plastic card. Cap size should be such that it inserted into the housing with little effort.

After that, the body ballast fix missing made holes in mounting segments the wires in the middle of the fluorescent lamp, as shown in Fig. 3.

Derived from the case wires, laying them along the filament lamp and in securing several places transparent adhesive tape, solder to the pins on two ends lamp. On the ends you can to wear, pre-heating, lids from plastic bottles.

The only drawback of the resulting lamp - it can be paid only in the cartridge around which there is an empty seat diameter not less than the length application of the lamp. Although, if wrapped around the cartridge to the cap already fixed in place in the lamp, this the disadvantage can be overcome.

Author: A. Nickow, G. Shadrin Kurgan region.