In the author's article "ViPer-100A and pocket charger based on it" ("Radio", 2002, № 11) described a device for charging car rechargeable batteries. As by simple modifications to turn it into stable power source told in the article.

In [1] described the charger on the chip VIPer-100A, providing the required charging current for the battery at the beginning and the voltage on it at the end of charging. In the development of specific requirements to its parameters is not were required.

However, it is possible by simple improvements to turn this charger the device in the stabilized power supply with a very high rate.

To do this, refer to the computer-aided design program SMPS based VIPer-chip [2], and the step of determining the output filter Output Type (see Fig. 9 in [2]) instead of the established Direct select Self - standard U-shaped LC filter. Therefore, you have to tighten the requirements to the value of the ripple the voltage at the output device in the Output Ripple in the window of the First Cell Ripple set to 0.5 and In the Second Cell Ripple - 0,02 V. On the toolbar program

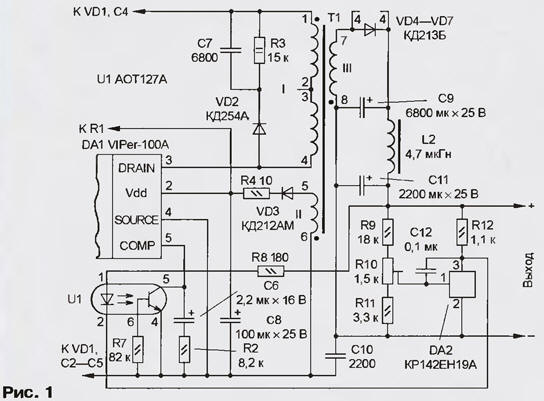

DS (see Fig. 6 in [2]) will change the way Primary regulation Regulation on Secondary Regulation. As a result, the SMPS circuit shown in Fig. 2 in [1], a few changes. A fragment of a modified circuit shown in Fig. 1. Numbering elements continues the previously adopted. Resistors R5R6 and microammeter RA1 exclude it.

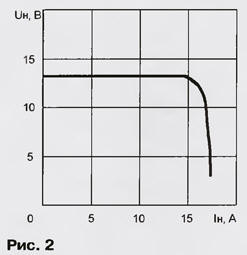

The essence of the changes is to introduce into the SMPS secondary control loop, whereby the source parameters significantly improved: when output the voltage of 13.6 V and rated current of the load 6 And the amplitude of the output ripple voltage will not exceed 15 mV. This is achieved by adding to the device chip DA2 and optocoupler U1. Especially noticeable improvement stabilizing properties SMPS for his load to the characteristic shown in Fig. 2 (compare with Fig. 4 in [1]).

The performance in the secondary control loop (it depends on the ratio the gain of the Gain optocouplers Optocoupler) defines the resistor R8. There is also and a fundamentally new property modified SMPS - time soft start Soft Start Time, which depends primarily on the capacity capacitor C6. The default DS sets the values of the gain the optocouplers and the time for soft starting is equal to 1 and 10 MS, respectively. Leave time soft start for retrofits SMPS without change, and the gain optocoupler will increase to 2, which refer to the window VIPer and Regulation Parameters (see Fig. 8 in [2]), and reinstall the option. The values of elements secondary control loop, calculated by the program, and then refined in the developing device shown in Fig. 1.

In the process of regulation depending on the output voltage of the SMPS is changed the gain of the amplifier error signal to the PWM controller. For this emitting diode of the optocoupler U1 through serially connected to tomograhy to give effect to the resistor R8 and the chip DA2 is connected to the output of the device. The Resistor R12 Is ballast in the food chain stabilizer DA2, and the capacitor C12 is noise in the control circuit. Resistive divider R9 - R11 set the operating point, choosing an initial current of the diode of the optocoupler. Light the flux of the diode regulates the current, respectively, and equivalent the resistance of the collector - emitter of the phototransistor is connected parallel compensation circuit R2C6.

Assume that, under the influence of destabilizing factors will increase the output the voltage of the SMPS. Consequently will increase the voltage at the control input (pin 1) chip DA2 and the flowing current. Therefore, the current emitting diode will also increase, and the equivalent resistance of the collector - emitter phototransistor is reduced. In reference [3] in Fig. 10 shows a graph illustrating the dependence of the gain of the voltage amplifier error signal A3 (see Fig. 1 in [1]) that by reducing the resistance in the circuit compensation may be reduced by 27 dB or more compared to original installed. Thus, if you change the result of the resistance in the circuit compensation amplifier error signal by correcting the parameters of the switching pulse restores the previous value of the output voltage of the SMPS.

Additional node SMPS feedback is gathered on a small (17,5x25 mm) segment boards for prototyping. Connect it to the charger through the inductor L2 and the capacitor C9 on-Board charger replace other, more (6800 µf) capacitance. The reactor contains 22 a coil of wire sew-2 1,5-wound coil to a coil on the mandrel with a diameter of 3.8 mm, his magnetoroton two ferrite tube with a diameter of 3.5 and a length of 20 mm, used in high frequency chokes. Upper circuit on the output of the throttle sealed into the hole on the Board charger designed to resistor R6. In addition, a conductor connects the negative outputs of the charger and the secondary site. Collector and emitter circuit of phototransistor connected respectively to the input of the compensation (pin 5) and output 4 PWM controller twisted pair conductors MGTF. Trimmer resistor R10 - SDR-19A or other small-sized, capacitors C6-K53-30 or K53-19, C12 - km-5, resistors - ALT. Domestic chip CREE interchangeable foreign analogue of the TL431.

Stable power source forge bug! Before the first once finalized, the inclusion of the SMPS engine tuning R10 set in the bottom on the diagram position, to the output of the source is connected to the dummy load, and then include it in the network. Gently moving the engine up under the scheme, measure the voltage at the load, and once it is abruptly reduced from 15.3 to 13.6 In, the adjustment is stopped. In the future, the voltage at the load will be stable be maintained at this level. Current emitting diode of the optocoupler at this point should be set to 1...2 mA, which is less than the maximum allowable (15 mA). This augurs well for the high reliability of the developed device.

Note that in order to improve noise immunity DS "recommends" between pins 4 and 5 circuits DA1 to connect a capacitor with a capacitance of 1000...2000 pF.

On the company's website address STMicroelectronics <http://us.st.сom/stonline/prodpres/discrete/vipower/faq/vipfaq.htm> placed FAQ (Frequently Asked Questions - frequently asked questions), in which those interested can find the answers to the issues associated with the calculation of SMPS based chipset series VIPer. This same section, translated the author in Russian language, with some additions.

Literature

Author: S. Kosenko, Voronezh