The throttle body (cdhs 2112-1148010-32) is an Electromechanical node injection system and largely determines the normal operation of the engine.

The throttle body includes a mechanical throttle, fittings for hose connection of heating system cdhs, fitting to connect the hose to the crankcase ventilation engine idle (idle), fitting to connect the hose system purge adsorber (in the absence of the adsorber system currently fitting the cover), the position sensor throttle and idle control, a screw for adjusting the end position of the throttle and the two screws to factory (technological) adjustments.

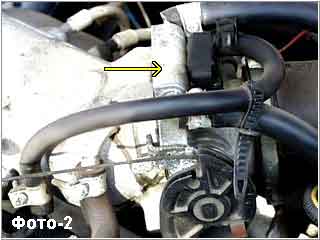

For better mixing in the throttle body can also be heated. This channel (see photo 2) is associated with the engine cooling system.

During operation of the engine coolant circulates through the throttle body and after warming up the engine to heat kdz. When passing through the throttle body is warmed up and engine intake air.

In the operation of a vehicle, it is necessary to monitor the condition of the hoses, because in some places they are subject to abrasion from contact with other elements of the engine.

Photo 3 shows the hose connecting the channel of the throttle body to drain the sump - tion gases of the engine with the cylinder head.

This channel provides a flow of gases from the crankcase of the engine in zaproszenie space. Next on the inlet tract crankcase gases are mixed with air and enter with him into the combustion chambers of the engine. Thus venting of crankcase gases from the engine idle (idle). Accordingly, the malfunction of the engine or the oil separator can lead to higher CO content in the exhaust gases.

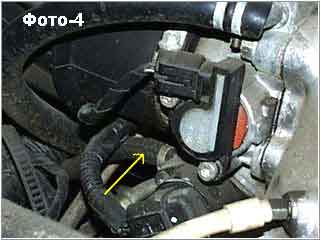

If the car is set to the adsorber to purge the throttle body provides a flow channel of the fuel vapors in zaproszenie space through the channel of the additional air regulator idling (IAC) (see photo 4). As the air through the IAC, fuel vapors from the adsorber fall into the intake tract to bypass the throttle. Accordingly, when a malfunction of the purge valve canister (KPA) on some operating conditions of the engine fuel mixture can be sufficiently rich that may affect engine operation.

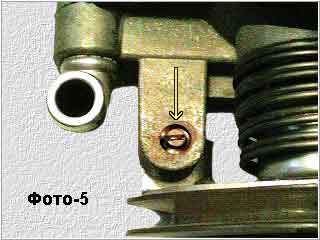

Work all of the items in any of the settings of the throttle body, usually not needed. However, in this design, in my opinion, there is an annoying fault. The fact is that although the throttle body and has a separate channel for minimum air supply, not in use and plugged.Thus, if there is a situation where the throttle is closed and the IAC for any reason (for example faulty) did not provide a flow of air to bypass the throttle, the engine just stalls (because there is no airflow, and fuel supply). Such situation is possible and a number of other reasons. Nevertheless to locate the car Parking lot or service station you can and without any problems, if, respectively, to set the initial position of the throttle. On the throttle body there is a screw for this adjustment (see photo 5).

With this screw should try to configure the minimum momentum Ho - Lastovo stroke (usually ~600-650 rpm). But it should be remembered that slightly opened throttle valve non - minuano will shift the initial position of TPS (sensor throttle position). In this regard, require initial adjustment provisions of TPS. Adjustment of the minimum idling speed should be warmed-up the engine and when the consumers of engine power.

The sequence of actions:

1. warm the engine to operating temperature

2. switch off ignition and connect the instrumentation necessary

3. disconnect the idle speed regulator

4. loosen the screws attaching sensor, throttle position 5. the adjustment screw end position of the throttle to lift her obviously greater angle

6. to start the engine

7. the adjustment screw end position of the throttle to adjust the minimum idling speed

8. to adjust the initial position TPS sensor and fix it

9. turn off the ignition

10. disconnect the battery and non-standard measuring devices

11. connect the connector of the idling regulator.

12. connect the battery

13. to smoke :o)

However, to perform this operation is not as easy as it seems at first glance. The problem is that the manufacturer took care of that this setting may be problematic, and for some impossible. The adjustment screw is planted on the paint and crank it happens very rarely. Possible solutions to this problem in the near continuing...

Publication: www.cxem.net